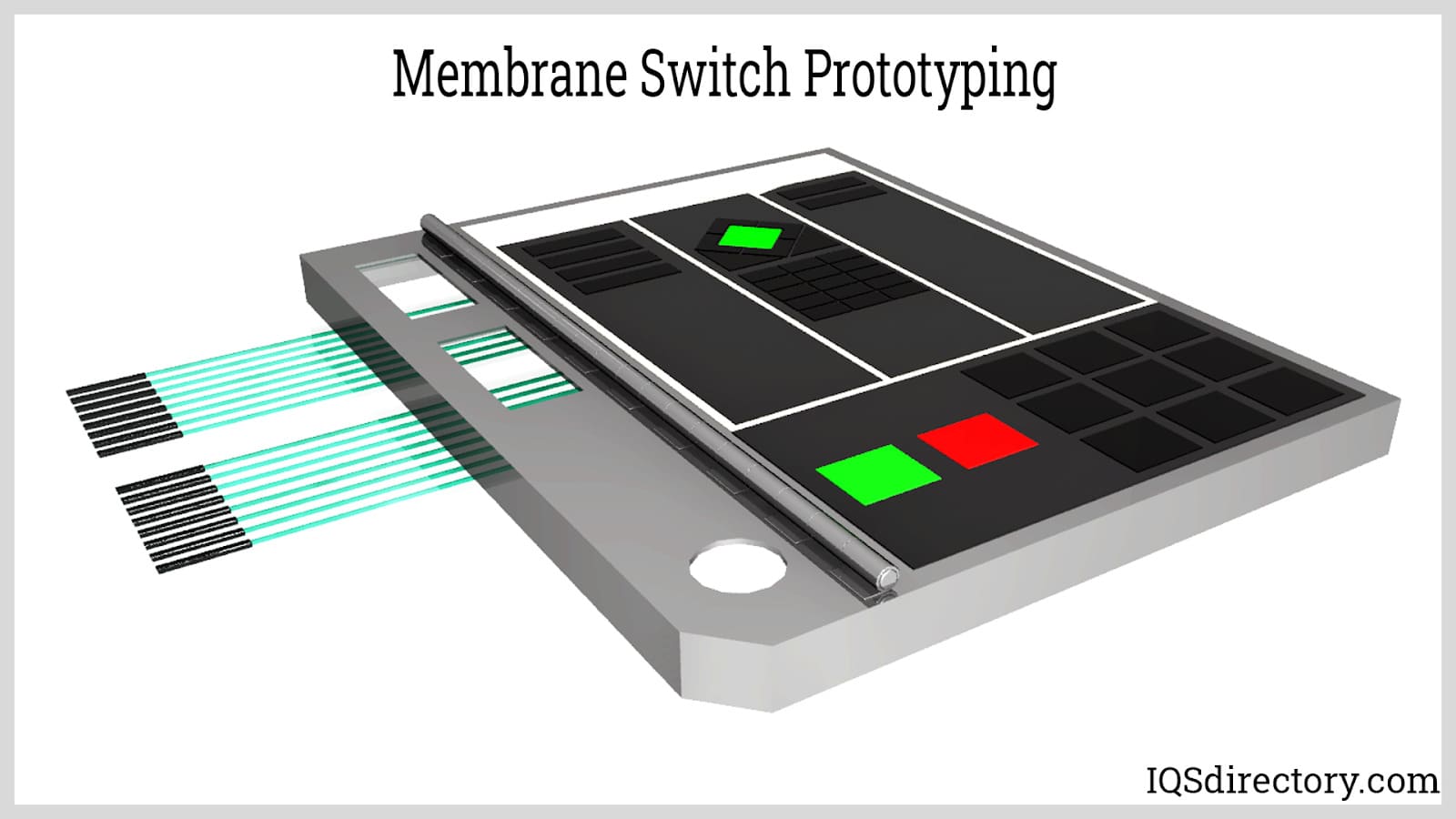

A good membrane switch manufacturer offers adaptable design options for unique applications.

A good membrane switch manufacturer offers adaptable design options for unique applications.

Blog Article

Everything About Membrane Change: Recognizing Its Style and Performance

When you consider the control user interfaces in contemporary devices, membrane layer buttons usually enter your mind. These components are greater than just switches; they blend style and functionality perfectly. Recognizing just how they work and what makes them efficient can alter your perspective on daily electronic devices. But, there are nuances to their design and efficiency that you may not understand. Allow's explore what collections membrane changes besides other control systems.

What Are Membrane Buttons?

Membrane layer switches can likewise be customized relating to shape, dimension, and graphics, allowing makers to create one-of-a-kind user interfaces tailored to certain items. On the whole, membrane buttons play a significant duty in improving individual experience across a wide array of applications.

Just How Membrane Layer Switches Over Work

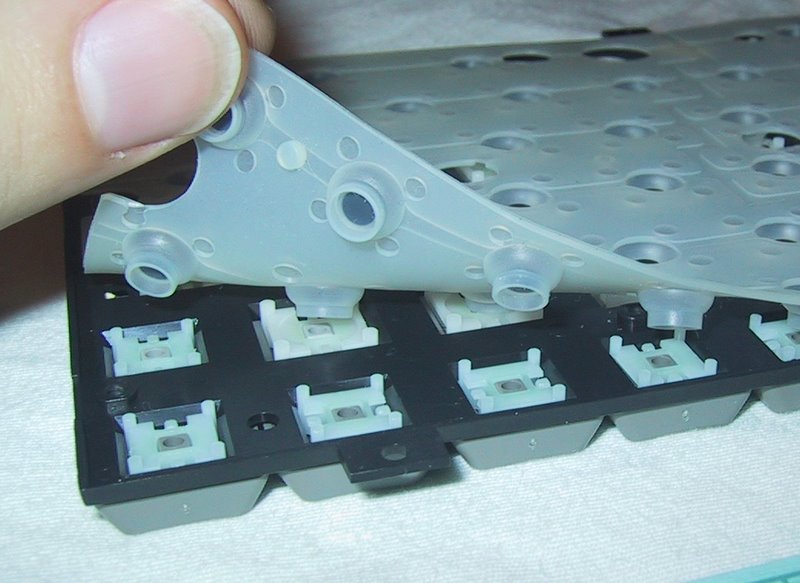

When you press a key on a membrane layer button, it triggers a straightforward yet effective system. The top layer, frequently made from adaptable product, lowers onto a conductive layer beneath it. This activity bridges the gap between conductive traces, finishing an electric circuit. As quickly as the circuit shuts, it sends a signal to the tool's controller, which analyzes your input.

You'll see that the tactile comments differs based upon the button design, providing either a soft click or a much more noticable action. As soon as you release the secret, the membrane layer returns to its original position, resuming the circuit and stopping the signal. This procedure occurs nearly instantly, ensuring a responsive customer experience.

Membrane layer buttons are popular due to their durability and resistance to dirt and moisture, making them suitable for numerous applications, from house devices to clinical gadgets. Comprehending this procedure aids you appreciate their widespread usage.

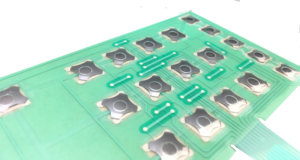

Key Components of Membrane Layer Buttons

Understanding the vital components of membrane layer buttons is essential for grasping their performance and design. The safety layer guards against ecological factors and use, prolonging the button's life-span. By comprehending these elements, you'll acquire insight into how membrane changes operate and their importance in numerous applications.

Materials Used in Membrane Switch Layout

The performance and longevity of membrane switches over greatly rely on the products utilized in their layout. You normally encounter polyester and polycarbonate as key substratums because of their superb strength and adaptability. These materials stand up to scrapes and chemicals, making them excellent for requiring atmospheres.

The conductive layers often make use of silver or carbon, picked for their integrity and conductivity. membrane switch manufacturer. Silver gives exceptional efficiency, while carbon is a cost-efficient alternative. For the overlay, you might take into consideration a matte or glossy coating, relying on your visual needs and user experience

Adhesives play a necessary function also; they bond layers securely and assure longevity. Ensure to pick adhesives that endure environmental aspects like temperature and humidity. Do not overlook the relevance of an excellent printing technique for graphics, as it boosts both capability and visual charm. Selecting the ideal materials will certainly ensure your membrane layer switch stands the test of time.

Layout Factors To Consider for Membrane Buttons

While developing membrane layer switches, go to this web-site it's important to think about different aspects that affect their performance and customer experience. Start by concentrating on the design and button dimension; ensure they're intuitive and very easy to browse. Think about the responsive responses you wish to provide-- will users need a noticeable click or a softer touch? In addition, consider the products you'll make use of, as they'll influence longevity and aesthetics.

Validate your layout accommodates ecological variables, like wetness or temperature variations, which could influence performance. By carefully thinking about these elements, you'll develop a membrane button that enhances use and satisfaction.

Applications of Membrane Switches

Membrane layer buttons are functional components discovered in different applications, from industrial tools to customer electronic devices. You'll see their impact in makers that require long lasting interfaces and in gadgets that take advantage of sleek layouts. Recognizing these applications assists you appreciate the functionality and usefulness of membrane switches in everyday modern technology.

Industrial Tools Use

When you're aiming to enhance the functionality of industrial equipment, membrane buttons use a reliable service that combines toughness with user-friendly style. These switches are perfect for severe settings, providing resistance to dirt, moisture, and chemicals. You'll locate them in control panels for manufacturing devices, a/c systems, and clinical gadgets, where precision and responsiveness are vital. Their low profile suggests they fit flawlessly into numerous tools, saving useful space while keeping convenience of use. With personalized graphics and backlighting options, you can produce an intuitive user interface for operators, enhancing performance and security. And also, their long lifespan reduces maintenance costs, making them a clever investment for your commercial applications. Welcome membrane switches to enhance your operations and enhance overall efficiency.

Customer Electronics Combination

In the domain of customer electronics, membrane buttons play a necessary duty in enhancing user interaction and device performance. You'll find them in tools like microwaves, remotes, and pc gaming consoles, offering a seamless means to connect with modern technology. Their sleek layout allows for very easy assimilation into numerous products, making controls intuitive and straightforward. With their capacity to integrate graphics and backlighting, you can appreciate a modern-day aesthetic that complements this content the tool's general look. Membrane layer buttons likewise guarantee resilience and resistance to dust and wetness, prolonging the life expectancy of your electronic devices. By picking membrane layer switches, you enhance not just the functionality but likewise the design of your gadgets, making daily communications smooth and pleasurable.

Advantages and Negative Aspects of Membrane Buttons

While membrane layer buttons provide a range of benefits, they also come with some downsides that you ought to consider. One significant benefit is their portable layout, making them perfect for space-constrained applications.

Membrane layer buttons can have a much shorter life-span contrasted to mechanical switches, particularly under find this heavy use. They can likewise be much less responsive, which may influence individual comments throughout procedure. Balancing these pros and disadvantages will certainly help you identify if membrane buttons are the appropriate fit for your project.

Frequently Asked Concerns

How Much Time Do Membrane Switches Over Typically Last?

Membrane layer switches normally last in between 5 to one decade, depending upon use and environmental problems. You'll want to examine aspects like wear, exposure to wetness, and temperature changes to gauge their long life effectively.

Can Membrane Layer Switches Over Be Customized for Certain Layouts?

Yes, you can tailor membrane buttons to fit certain designs (membrane switch manufacturer). You'll have the liberty to choose colors, shapes, and designs that match your task's demands, ensuring they mix flawlessly with your overall visual

What Is the Price Variety for Membrane Switch Manufacturing?

The cost variety for membrane layer button production usually drops between $1 and $10 per system, depending on elements like style complexity, quantity, and materials. You can obtain quotes from makers to find the very best alternative.

Are Membrane Changes Water-proof or Resistant?

Membrane switches can be created to be waterproof or immune, depending upon materials used and building methods. If you require them for damp settings, ensure you define those needs throughout the style procedure.

Just How Do Membrane Changes Compare to Traditional Buttons?

Membrane layer switches are typically thinner and more flexible than conventional switches, supplying a streamlined style. They're often easier to clean up and integrate, however could not provide the tactile responses you're made use of to with mechanical alternatives.

Conclusion

Report this page